The spiral wound gasket’s popularity is due to several factors:

• It is ideal in high temperature, high-pressure, and corrosive applications.

• A wide variety of available gasketing material allows

engineers, contractors, and industry professionals to tailor the gaskets

to their specific application. (See material options, below.)

• The v-shaped metal strip, called the winding, forms a tight seal with spring like qualities.

• It creates an excellent seal once compressed under the load of bolts or studs.

• Upon compression the filler fills minor imperfections in the flange facing creating a near perfect seal.

There are many types of spiral wound gaskets, the most common four are:

CG Style– The most commonly used and widely available configuration of spiral wound gaskets. CG Style gaskets have a solid metal ring on the outer diameter referred to as the centering guide (CG). This guide allows the installer to more accurately center the gasket on the flange face while providing strength on the outer ring. CG style gaskets are used with both flat and raised-face flanges in a wide variety of applications.

CGI Style– Like the CG Style described above, CGI gaskets have an outer ring, but they also offer an internal ring protecting the inner diameter of the gasket against heat, corrosion and blow-outs making it ideal in vacuum applications. CGI Style gaskets can be used with both flat and raised-face flanges.

R Style– The most basic configuration of spiral wound gaskets, the R-Style consists of only the metal winding and the filler materials. The inner and outer diameter are reinforced by several layers of the winding material without the filler. The inner portion of the R-style gasket is made up of winding and filler material. This style is used with tongue and groove, flat-faced to grooved, and male to female flange connections. They are also regularly used in valve bonnets and pump casings.

RIR Style– Is similar to the R-Style gasket in its basic construction but has an inner liner ring that acts as a reinforcement. The inner ring creates a compression stop and fills the void between the inner diameter of the gasket and the flange bore. This reduces the accumulation of solids and reduces tubulation of fluids. RIR-Style gaskets are used on male and female flange connections.

The construction of spiral wound gaskets can be customized with the following material options:

Inner and Outer Rings:

• Carbon Steel

• 304

• 304L

• 316

• 316L

• 317L

• 321

• 347

• 310

• Monel®

• Nickel

• Titanium

Winding Materials:

• 304

• 304L

• 316L

• 317L

• 321

• 347

• 310

• 309

• 430

• Alloy 20

• Titanium

• Inconel® 600

• Inconel® 625

• Incoloy® 800

• Incoloy® 825

• Inconel® X750

• Hastelloy® C276

• Hastelloy B2®

• Nickel 200

• Zirconium

• Carbon Steel

• Monel®

• Duplex Stainless

Filler Materials:

• PTFE

• Graphite

• Flexicarb®

• Flexite Super®

• Ceramic

• Thermiculite® 835

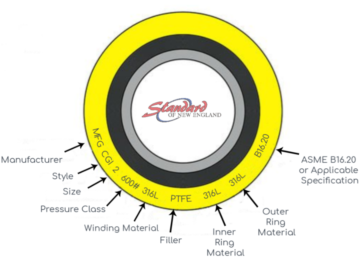

What do I need to know when ordering a spiral wound gasket?

• Style

• Size

• Pressure Class

• Winding Material

• Filler Material

• Outer Ring Material (if applicable)

• Inner Ring Material (if applicable)

• Are MTR’s required?