Everyone, it seems, is talking about buying domestic. It’s a common request from our customers. But what does it really mean? Working with partners who have taken the time to understand the numerous domestic requirements and guidelines provides you with reliable information and responsible quotations/bids that can prevent your company from making costly mistakes.

A few years ago, our customer asked us to provide a quote containing valves, pipe, fittings, flanges, expansion joints, and bolting hardware for a fuel oil piping system. Their stated requirement was that all material had to be AIS (American Iron and Steel) certified, which requires that all the metals used in a finished piping product need to be mined, melted, and machined in the U.S. Our proposal was appropriate with some exceptions taken on certain valves which were not available to meet AIS requirements by any manufacturer. We were not awarded the job. Our competitors and our customer failed to understand the stringent requirements of AIS and a purchase order was issued to one of the lower bidders who noted ‘domestic’ on their quote. However, ‘domestic’ and AIS are two very different things as they both learned the hard way.

About 8 weeks later, the owner of the project rejected the submittals our customer provided from the low bidder, noting that the material did not meet AIS as required. Blinded by the lower costs that were irresponsibly provided and now behind schedule, our customer had to save face and finish the job. They asked for a meeting with us to go over what supplying goods to AIS requirements involves and what steps we had to go through to provide material to this specification. It can get exceedingly complex. For this particular project, just to meet AIS, the consulting engineer had to change the specification on the class 300 valves from cast steel gate and globe valves to cast iron valves, and on a couple of the sizes they then changed the gate valves to large, flanged ball valves. Unfortunately, our customer had been caught off guard and had a hard time coming in on budget for this project.

When we ask customers to be more specific in their requests for domestic material they will often say “made here” or “made in the U.S.” When we ask for a particular specification, they might say the “Buy America Act” or “Buy American Act” not realizing these are two completely different Acts with different mandates. Furthermore, in addition to these two Acts, there are requirements such as DFARS, FARS, NAFTA, ARRA, and AIS that may also need to be met. Each of these requirements is unique and each can be a challenge to comply with. For example, some fitting manufacturers in this country purchase shapes in certain sizes overseas and only machine them here so they are unable to meet AIS, but on other sizes they can meet the AIS because the shape is formed stateside from raw material sourced here. The same can be said of flanges. Lots of flange mills in the U.S. procure forgings from overseas and machine them here. That process would meet domestic requirements but not AIS. We would all rather procure products from manufacturers in the U.S. who employ fellow Americans working in their factories. However, those who author these Acts and requirements often seem to have little knowledge about how industrial piping products are manufactured, making their goals not always attainable or economically viable.

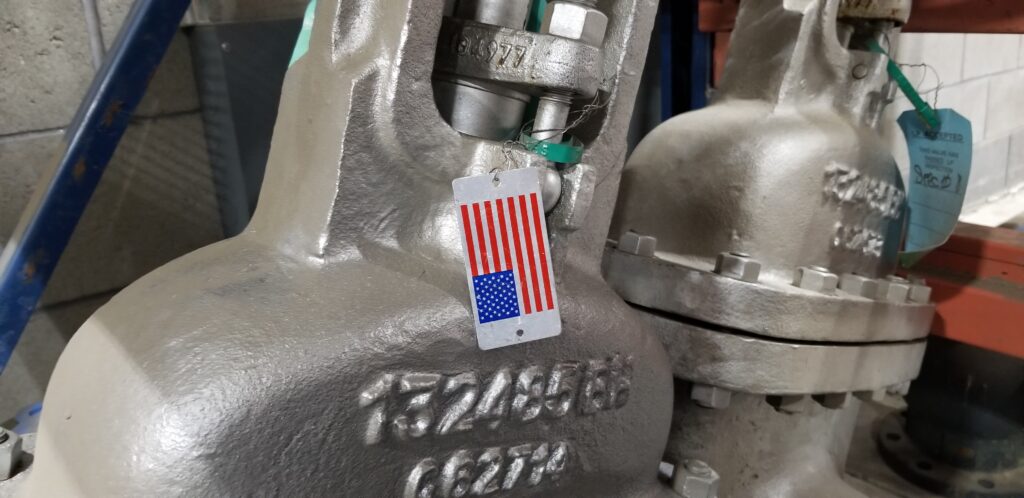

So, when you are involved in providing goods to these exacting requirements, often on some type of government or military facility, take your time and be careful. First, be sure that you understand the contract requirements. Second, don’t be duped by clever marketing ploys into thinking an American Flag sticker or tag affixed to a product means it meets any of the requirements mentioned above. According to The Flag Code, “the United States Flag should never be used for advertising purposes in any manner whatsoever.” Third, and most importantly, work with a knowledgeable partner who has your back.

Here at Standard of New England we strive to be informed on how the products we provide to industry are manufactured so that we can offer our customers guidance according to their particular specifications. If you’re working on a job with complex requirements, contact us at 603-436-1400 to speak to one of our knowledgeable salespeople or request a project consultation for more in-depth assistance.